We have extensive range of pumps for various applications, including pumps for transporting drinking water, rainwater drainage, sewage treatment and irrigation, as well as high-temperature, high-pressure water supply pumps for thermal power stations and nuclear power stations. We also have extensive know-how in technologies such as construction cost reduction technology, simulation technology and extending the service life of pumps after installation. We carefully analyse your requirements, offer individual advice and select the right products.

Magnetic Drive Pumps

Magnet drive designs have become the standard for applications requiring corrosion resistant pumps. Our Iwaki range of magnet drive pump designs offer a wide range of capabilities from general purpose and electromagnetic metering pumps with excellent controllability and accuracy fit smaller applications. The outstanding features of Iwaki magnetic drive pumps include Leak free, seal-less construction, Simple, modular construction for ease of maintenance, Non-metallic chemically inert materials offer excellent resistance to corrosive fluids.

Excellent performance and an extensive line-up of leading magnetic drive pump designs. Maximum flow range from 135 L/min to 5000 L/min to meet a wide spectrum of applications.

Main applications

- Surface treatment

- Water treatment

- Chemical processing

- Food processing

- Fluid handling needs in a variety of OEM equipment

Metering Pumps

When critical, environmentally hazardous, toxic, or flammable fluids and suspensions need to be reliably conveyed or metered in high-pressure processes, Iwaki range of pumps is the answer. Iwaki offers a complete line of controlled volume metering pumps to satisfy any metering application.

Iwaki provides a wide range of metering pumps to satisfy a variety of chemical feed requirements. These pumps have excellent features like high accuracy of chemical feed, excellent flow repeatability, high turndown ratio and control. Construction with chemical resistant materials improve corrosive resistance. Hydraulically-backed diaphragm pumps can withstand tough conditions in process applications.

Main applications

- Water treatment

- Chemical processing

- Waste water treatment

- Food processing

- New energy processing

- Motor driven metering pumps

Robust mechanical designs capable of withstanding aggressive installations and equipped to handle high pressure feed applications.

Pneumatic Drive Pumps

Pneumatic pumps have a critical role to play in industrial environments. Pneumatic pumps, apart from their use in transferring liquids from one place to another, are highly practical in air removing, construction and some other applications. Indigenously developed bellows pumps have long life and they also reduce the downtime. These pumps have long service life, contamination free design and no leakage of transfer medium.

Main applications

- Chemical feeding to washing equipment’s

- Circulation of wafer cleaning fluid

- Feeding of CMP slurry fluid

Rotary Displacement Pumps

Iwaki Rotary displacement pumps with distinct construction for transferring viscous liquids and slurries. These pumps are highly effective due to the following features:

– Suitable for transferring viscous liquids and slurry liquid (screw pumps)

– Pulse-less metering transfer (gear pumps)

-Ease of maintenance (rotary pumps)

-Easy to handle (tube pumps)

-Capable of transferring highly viscous, solid substances (hose pumps)

World’s first chemical gear pumps equipped with fine ceramic gears, hose pumps capable of transferring solid substances, tube pumps for multipurpose use from research laboratories to general industrial use, and sanitary type rotary pumps. Iwaki is working on various technical innovations of pumps.

Main applications

- Chemical and paper processing

- Water supply and sewage systems

- Food processing

- Research and experiment plants

- Drainage, waste discharge, recycling treatment plants

Air Pumps

Iwaki offers a wide array of pumps with a proven track record that have been tried-and tested. These pumps are available in a wide variety, starting with ultra-compact models for medical and analytical devices to vacuum pumps for general industrial use, these pumps continue to support the diverse needs of our customers. These pumps have gained a reputation for high reliability from different fields such as analytical equipment, test/inspection, and research laboratories. They are backed with features like low noise and vibration, compact size and capability to handle corrosive and high temperature gases.

Turbine Pumps

Turbine pumps are dynamic pumps, meaning they utilize fluid momentum and velocity to generate pump pressure. Turbine pumps are used in clean liquid applications that demand high head, low flow, compact design, and flexible operation. They’re used in a wide range of industrial applications such as cooling water circulators for lasers and other machines where high head is required. Turbine pumps are also found in small boiler feed services in bakeries, dry cleaners, breweries, chemical industry, cooling water, temperature regulator, drug manufacturing process etc.

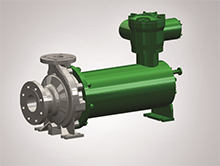

Hermetically Sealed Pumps

Hermag’s hermetically sealed design of the canned motor pump ensures that there is no leakage of the pumped liquid into the environment. This gives the canned motor pump technology a tremendous advantage when it comes to operational safety and environmental protection. Due to the no leakage feature, these pumps are perfectly suitable for handling explosive, toxic, corrosive, or flammable liquids. These pumps are known for its smooth and trouble-free operation, compact design, low noise and vibration characteristics. HERMAG pumps offers wide selection of materials, including Cast Iron, Stainless steel, Hastelloy and Titan, to cover an outstanding range of more than 600 liquids. HERMAG’s API and ISO ranges are designed for ultimate reliability and smooth operation in extreme conditions.

We also support mechanical spares for John Crane & Eagle Burgmann seals for various equipment’s such as pumps, reactors, filters and agitators.